Integrating the dispenser into the print cycle brings with it a significant cost reduction and is further step in the direction of Zero-Defect production

While the miniaturization of the products seemingly spelled the end for the dispensing process, today the miniaturization is the cause for its resurgence in the form of “post printing dispensing”. Stencils in use today are in the range of 100 - 200 µm. At this thickness, and depending on the complexity of the assembly, the volume of paste that can be deposited is at the limit or even slightly out of the tolerable range. One solution to this is the deployment of costly step stencils, through which on individually determined positions more paste can be deposited. Another solution, far more economical, is the deposition of the paste with a dispenser on all those areas where it is called for.

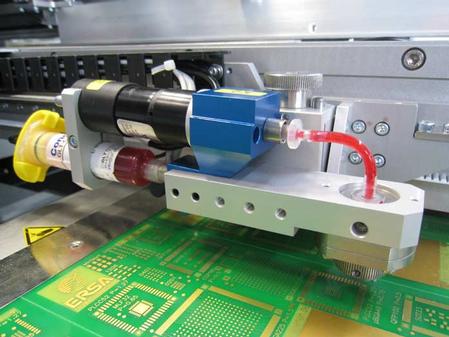

During discussions with their customers, it became clear to ERSA that this is a feature its customers would appreciate having available in the VERSAPRINT. Listening to these wishes and demands, ERSA acted and the dispensing feature is now offered as an option in the VERSAPRINT. With this easy to use and cost effective option, single dots and lines can be dispensed after the printing process. The dispenser option is based on the principle of the Archimedean screw, and it meets all the prerequisites for it to be able to very accurately place the dots. One or two dispenser units can be installed in the VERSAPRINT, so that two different media – either different pastes or paste and glue - are permanently available at the system, and they can be applied in one process step. The needle of the dispenser is automatically cleaned, the program cycle being programmable. Consistent, reproducible process parameters are therefore assured.

As is customary for ERSA designed products, the programs for the dispensing process are easy to generate. The user sees an image of the layout on the monitor, and the points where to dispense the media are set by zooming in and then “marking” the location. This represents the maximum in user friendliness. Individual parameterizations of the dispensing sequence for each location, including its subsequent inspection, are a matter of course. With the dispensing feature integrated into the printer, the user is gaining additional value from the printer, while at the same time increasing equipment utilization. All in all, a method to reach the shortest ROI!

hitech.gif)

.gif)