Valor® IoT Manufacturing Analytics solution for PCB Assembly

Company Information:

Name: |

Valor® IoT Manufacturing Analytics solution for PCB Assembly |

Category: |

|

Offered by: |

|

Valor® IoT Manufacturing Analytics solution for PCB Assembly Description:

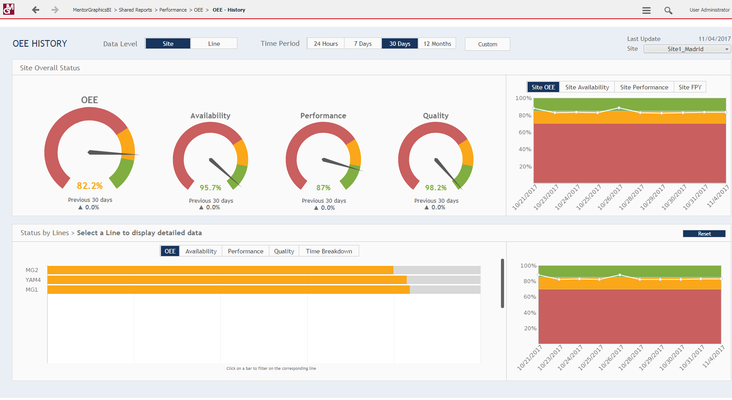

Improve manufacturing operations and decision making based on real time shop-floor information

Achieve goals for on-time delivery, eliminated waste, asset utilization, first pass yield, DPMO and total traceability.

Valor IoT manufacturing collects and normalizes data from every machine and process on the shop-floor into the Open Manufacturing Language (OML) ensuring end-to-end data coverage and enabling connection of the shop-floor with enterprise systems. Valor IoT Manufacturing analytics provides PCB manufacturing executives, line managers and manufacturing engineers with crucial information to make the best business and operation decisions to deliver quality products at lower cost, on time.

Highly visual information via dashboards, alerts and automated reports provides easy analysis of performance, traceability, quality, and the utilization of equipment and materials KPI's. Intutitive and easy to use self-service platform allows for easy creation of reports that fit every factory specific needs.

Features and Benefits:

Improve Order Fulfillment performance for increased customer satisfaction

- Track each customer work-order as product moves through factory

- Display current status of delivery against the due date

- Identify bottleneck in the production flow

- Provide secure environment for sharing web based reports

Improve Quality of the Process and the Product

- Track yield and DPMO at each process inspection or test station

- Instantly trigger Alerts with defined Upper or Lower Control Limits

- Automatically generate quality reports on intervals you determine

- Provide drill down analysis to determine root cause

Shorten the time to deploy the right corrective actions to provide the highest benefit

- Use of automated reports and alerts gives immediate visibility to the problem

- Drill down reporting with drag and drop selection of dimensions and measures

- Avoid wasting time and resources on chasing the wrong problems

Provide instant traceability reports of all manufactured products

- Achieve compliance with customer requirements

- Set up automated reports for traceability based on the PCB ID number, or component lot code/date code/reel ID

- Minimize any recall exposure to only the affected product

Improve product quality and supplier quality with traceability data

- Link the product performance at inspection and test to specific vendors and raw material date codes

- Compare quality between SMT suppliers at the level of component reference designators on the PCB assembly

- Quickly eliminate continued use of a bad component lot code, and isolate product built with a known bad component lot code

Improve asset management and utilization of capital equipment

- Track utilization data for each machine and line in the factory

- Track performance data for each process asset

- Associate and compare product quality with specific process assets

Valor® IoT Manufacturing Analytics solution for PCB Assembly was added in Oct 2011

Valor® IoT Manufacturing Analytics solution for PCB Assembly has been viewed 895 times

8 More Products from Mentor Graphics :