· What is the difference between SMT vacuum reflow soldering machine and ordinary reflow soldering machine?

· What problems can be solved by smt vacuum reflow soldering machine?

· What is the basic principle of vacuum reflow machine?

· How to choose smt vacuum reflow soldering machine?

After SMT machine soldering, there will be some voids in the solder joints. These inevitable voids will cause some potential risks to the quality of the whole product, and the most direct manifestation is that the life of the product will be far less than expected. Especially in aerospace, aviation, automotive electronics, medical electronics and other industries that require very high stability and reliability of products, the voids rate of soldering points also becomes an indicator of whether the product is qualified.

The causes of these solder join voids are various, such as solder paste, PCB surface treatment, reflow temperature curve setting, reflow environment, solder pad design, microholes, solder pad empty, etc. But the main reason is often caused by residual gas in the molten solder during soldering.

As the molten solder solidifies, these bubbles cool down and form a solder joint voids. It is a phenomenon that will definitely occur in soldering, it is difficult to have all solder joints in electronic assembly products to achieve zero voids.

Due to the influence of void factors, the quality reliability of most solder joints are uncertain, resulting in the decrease of mechanical strength of solder joints, which will seriously affect the thermal and electrical properties of solder joints, thus affecting the final product performance.

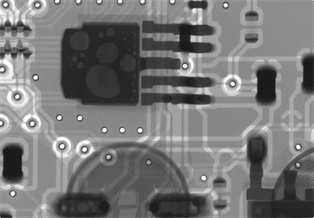

Chip Component Solder Joint Voids

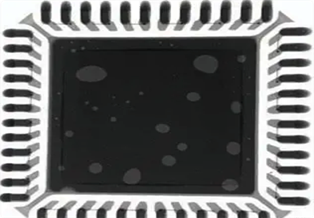

BGA Solder Joint Voids

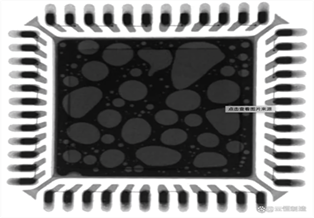

IC Component Solder Joint Voids

Normally, after inspection by I.C.T-7900 X-ray, the void rate of some soldered products can be as high as 30%, while according to IPC-7095C, the void rate is greater than 35%, and the void diameter is greater than 50% of the solder pad diameter is process controlled limit value. Generally speaking, customers with higher requirements place PCBA production orders for EMS. The void area is also one of the indicators. If it exceeds 25% of the solder ball area, the product will be considered unqualified and require repair.

Comparison of LED solder joints:

The void rate sintered by vacuum reflow soldering machine I.C.T-LV733 is low, and the void rate is about 1%, please check the following picture.

The void rate of ordinary reflow soldering machine sintering is low, from the picture below, there are a lot of air bubbles.

It does not mean that we all choose vacuum reflow soldering. If your product quality requirements need very high and the stability, you can consider our I.C.T-LV733

How to solve the problem of void, there will be use vacuum reflow soldering machine. Soldering in vacuum environment can fundamentally solve the oxidation of solder in non-vacuum environment, and due to the effect of internal and external pressure difference of solder joint, the bubble in solder joint is easy to overflow from the solder joint, so as to achieve low bubble rate or even no bubble, and ultimately improve the thermal conductivity of the device fundamentally. The void rate of vacuum reflow soldering is generally below 3%, which is much less than that of nitrogen and lead-free reflow soldering.

The basic principle of SMT reflow soldering machine:

1. Provide extremely low oxygen concentration to reduce the oxidation degree of flux.

2. The oxidation degree of the flux is reduced, the volatile gas reacting with the oxide and the flux is greatly reduced, and the possibility of voids is reduced.

3. Flux melting flow in vacuum environment is better, the buoyancy of bubbles is much greater than flux flow resistance, and bubbles are easily discharged from flux melting.

4. There is a pressure difference between the bubble and the vacuum environment, the bubble buoyancy increases, and the bubble is not easy to produce oxidation reaction with the flux.

How to choose smt vacuum reflow soldering machine?

1. Degree of Vacuum sealing: vacuum reflow soldering to ensure the vacuum degree of furnace work, by checking whether the original leakage rate is up to standard.

2. High quality thermal insulation material: The thermal insulation material in vacuum reflow soldering is also carried out in a vacuum state. This requires thermal insulation materials to have certain characteristics such as high temperature resistance, small thermal conductivity, and low vapor pressure. The commonly used insulating materials are tungsten, tantalum, graphite, etc.

3. High performance of water cooling device: when vacuum reflow soldering works, all parts are in the heating state. Because the furnace is in the vacuum state and is not connected with the outside world, the heat discharge system must be set up with high quality. The water cooling device is the first to be recommended here. The shell and cover of vacuum reflow soldering machine, conduction and disposal of electric heating elements, and hot interval parts should be specially set with the water cooling device. In this way, it can be ensured that the structure of each component will not be deformed or damaged under vacuum and high heat conditions.

4. Void detection with X-ray I.C.T-7900: Compared with the void rate of common reflow soldering and vacuum reflow soldering, can the void rate of vacuum reflow soldering be lower than 3%, or even reach 1%.

I.C.T-LV733 vacuum reflow soldering machine can fully meet the above requirements, you can contact us for consultation.

»

»