Did you know that certain stencil cleaners can help cut down your overall costs like labor costs, printing errors, and factory and environmental hazards? We have found that often times SMT Factory Owners and CEOs tend to overlook the costs within the stencil cleaning process that affect many factors down the operation line. It is not just the cost of the machine you are purchasing it is the overall cleaning system that you are investing in which has an effect on many different areas and should be addressed when considering your best stencil cleaning method. Here is a list of questions to consider when addressing your total investment in a Stencil Cleaning Process:

How many SMT lines are in your factory?

How many stencils are currently in use?

How do you currently clean stencils? Manually? Ultrasonic? Fully Pneumatic?

How much cleaning liquid do you use per month?

Can the process effectively clean fine and ultra fine- pitch apertures?

Does the process offer water and chemical reclamation/recycling?

Is the process fire safe? chemical safe?

Are there any health or safety hazards to consider?

What is the maintenance and potential downtime?

Does the machine consider current and future environmental regulations?

Is it cost Effective, High ROI?

Is there a built-in clean checking system?

Can the process clean dry as well as fresh paste?

Are there other objects to clean such as misprints?

What is the environmental impact?

What are the labor costs of each process?

What are the operating costs?

Is the machine fully automatic or semi-automatic? Programmable?

Does the machine free the operator from the cleaning process?

Does the machine require a specialized operator?

Does the machine require manual re-positioning?

What are the cleaning and drying times?

Does the drying process leave a film?

What size stencil does the process clean best?

Does the machine clean small stencils efficiently?

Does the machine handle large stencils?

Does the process recycle cleaning solution?

Lowers overall cleaning solution usage?

What is the electricity usage?

Overall Considerations:

Total Costs

Labor

Productivity

The Environment

Time

PCB Defects

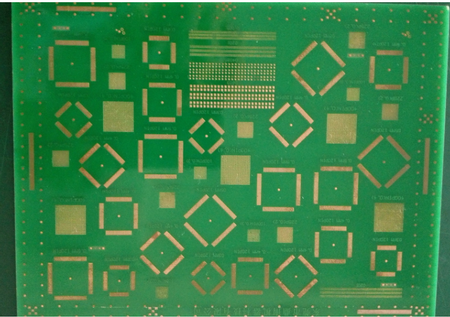

Misprinted PCB

Solution Usage

.png)